Environmental Initiatives

As a responsible member of society whose task lies in the preservation of the global environment, the Company will make every effort to contribute to human health and the preservation of the global environment in each phase of its corporate activity.

Only in this way will we be able to count on a successful future not only for our company, but for the world.

Target Domains

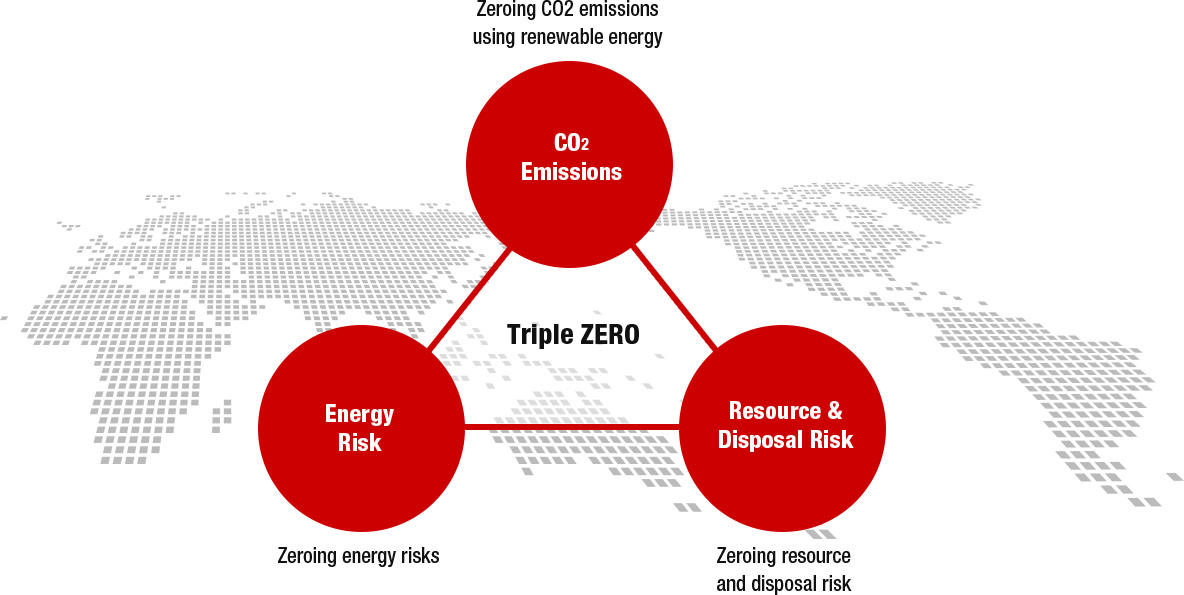

To respond to issues Honda considers to be important in the environmental domain, namely climate change, energy issues, and efficient use of resources, Honda Trading aims to realize a “zero environmental burden society,” through its commitment to business activities based on the “Triple Zero” concept.

Triple Zero Approach

| Zeroing CO2 emissions using renewable energy | To address climate change issues, Honda is striving to eliminate CO2 emissions in products and business activities in the future by utilizing renewable energy. |

|---|---|

| Zeroing energy risk | To address “energy issues,” Honda is striving to eliminate energy risks in the future, such as those caused by a dependence on fossil fuels. |

| Zeroing resource and disposal risk | To address the need for “efficient utilization of resources,” Honda is striving to eliminate risks across the entire product life cycle, from the resource procurement stage to the used product recovery and disposal stages. |

Mitigating Climate Change and Energy Risk

Initiatives in the field of transportation

We carry out CO2 emissions management in the transportation (within the scope of transporter responsibility), and help to improve the efficiency of transportation in cooperation with transport companies.

In order to improve transportation efficiency, we propose the most appropriate logistics across different business operations and propose modal shifts* and the prioritization of highly-efficient ocean freight.

We are also engaged in initiatives for the active use of returnable containers(materials) and the reduction in packaging materials by making changes to packaging specifications, to the extent that such changes do not affect the products. These initiatives not only lessen the burden on the environment, but contribute to lower packaging costs for customers.

* Modal shift: A shift towards transportation and means of transportation with a low impact on the environment.

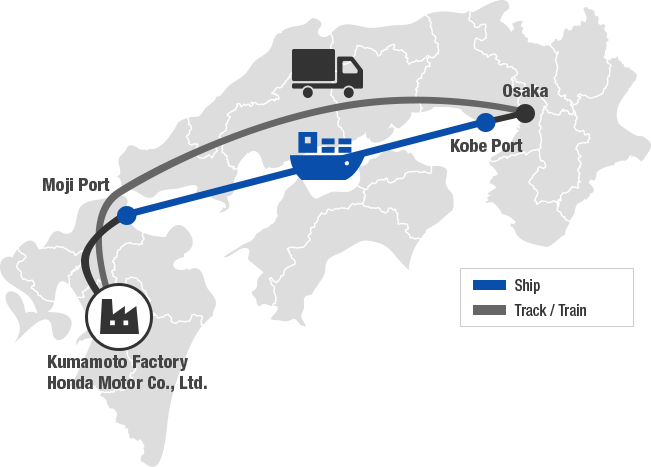

Examples of greater transport efficiency

For domestic freight from Kumamoto Prefecture to Osaka Prefecture in Japan, modal shift initiatives are underway, involving a shift from truck transport alone to efficient transport by ship between Moji Port and Kobe Port. This has resulted in a reduction in annual CO2 emissions from transport on these routes of approximately 30%.

Initiatives at aluminum manufacturing companies

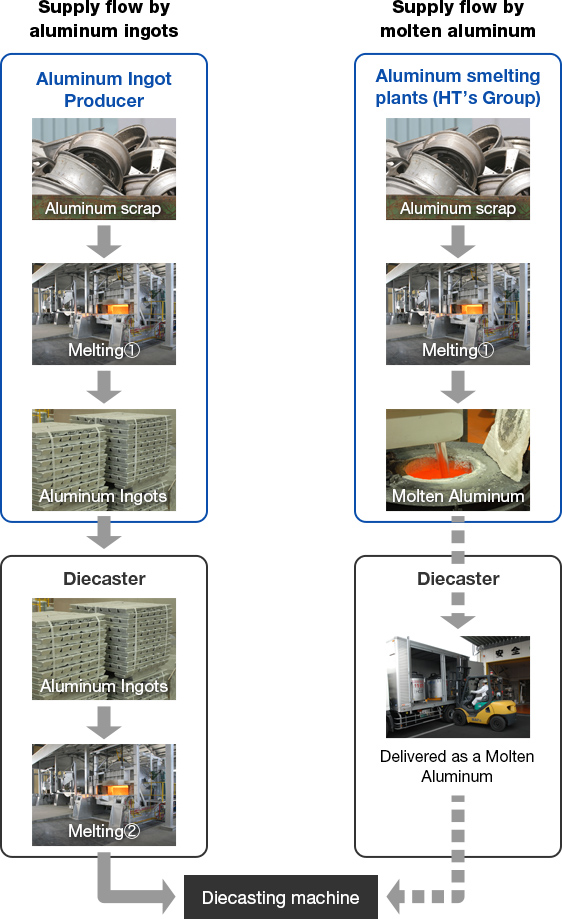

At aluminum manufacturing companies of our group, we supply molten aluminum from plants built in the vicinity of our customers.Scrap aluminum, such as offcuts, generated at our customers’ factories are recovered and melted down as valuable aluminum assets (factory return materials) and once again delivered to our customers’ factories as aluminum raw material.

System for supplying molten aluminum

The standard process for manufacturing aluminum products involves aluminum manufacturers melting the aluminum (first melting process) to produce ingots (solid) which are then delivered to manufacturers. The manufacturers then melt the delivered ingots at furnaces installed at their own plant (second melting process) and manufacture aluminum products.

By supplying manufacturers with molten aluminum, we are able to reduce the standard double aluminum melting process (which requires a huge amount of energy) to a single process, contributing to reducing the environmental impact of manufacturing aluminum products, including the reduction of smelting resources (oil, gas, and electricity) and that of total CO2 emissions.

In 1994, we established the Honda Group's first aluminum smelting plant in Kumamoto, and we have since gone on to open smelting plants in Gunma and Saitama. Overseas we have developed operations in Indonesia and China.

Efficient use of resources

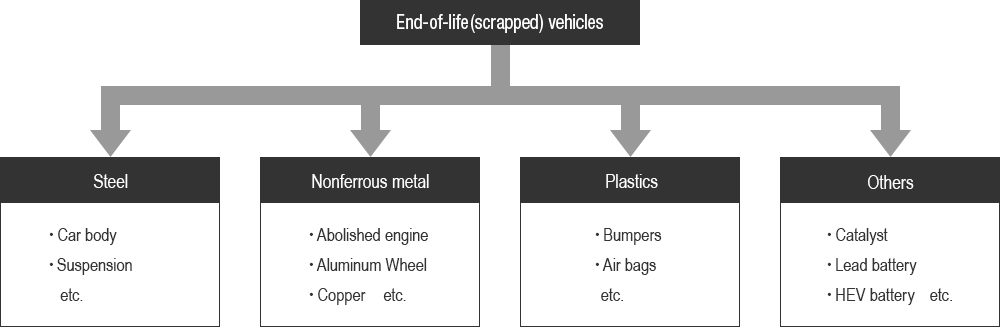

We recycle scrap resources collected from manufacturing processes and used vehicles in all material domains, including iron, plastics, and non-ferrous metals.

Resources cycle for end-of-life (scrapped) vehicles

In Japan, we are involved in an initiative to improve the resources flow for automobiles. End-of-life (scrapped) vehicles recovered from car dealerships are dismantled, and iron, plastics, aluminum, rare earth metals and other scrap materials are recycled.

We have built efficient systems to facilitate the smooth implementation of reuse and recycling and aim to contribute to the expansion of an environmentally-friendly recycling society.

Paper resources recycling

We implement measures to collect used paper produced by Honda Group offices in Japan. The used paper is transformed back into resources at paper manufacturing companies, and then reused in brochures and other documents by the Honda Group.

Other Initiatives

Initiatives in the field of purchasing

As a Honda Group company, we take part in Honda Green Purchasing Activities, through which we procure materials and parts that have small environmental footprints, including matters related to chemical substances.

These activities are based on Honda’s guidelines, and we purchase items, considering environmental burden reduction in all stages of a part’s lifecycle. We also promote the management of chemical substances, which have particularly detailed regulations, in line with Honda’s management standards.

Initiatives in the field of sales

We contribute to the reduction of environmental burden by recycling waste generated by auto dealers.

- ・Use of used lead batteries as raw materials for new lead batteries.

- ・Refine waste engine oil and supply it as recycled fuel oil to production companies.

Recruitment

Recruitment Contact Us

Contact Us